•The demand for large and complex parts in sectors like energy generation, railway, and heavy equipment is growing rapidly. However, the manufacturing process for these bulky parts faces several challenges:

•The REED Project provides a Manufacturing as a Service (MaaS) platform to address these challenges. This innovative digital platform will:

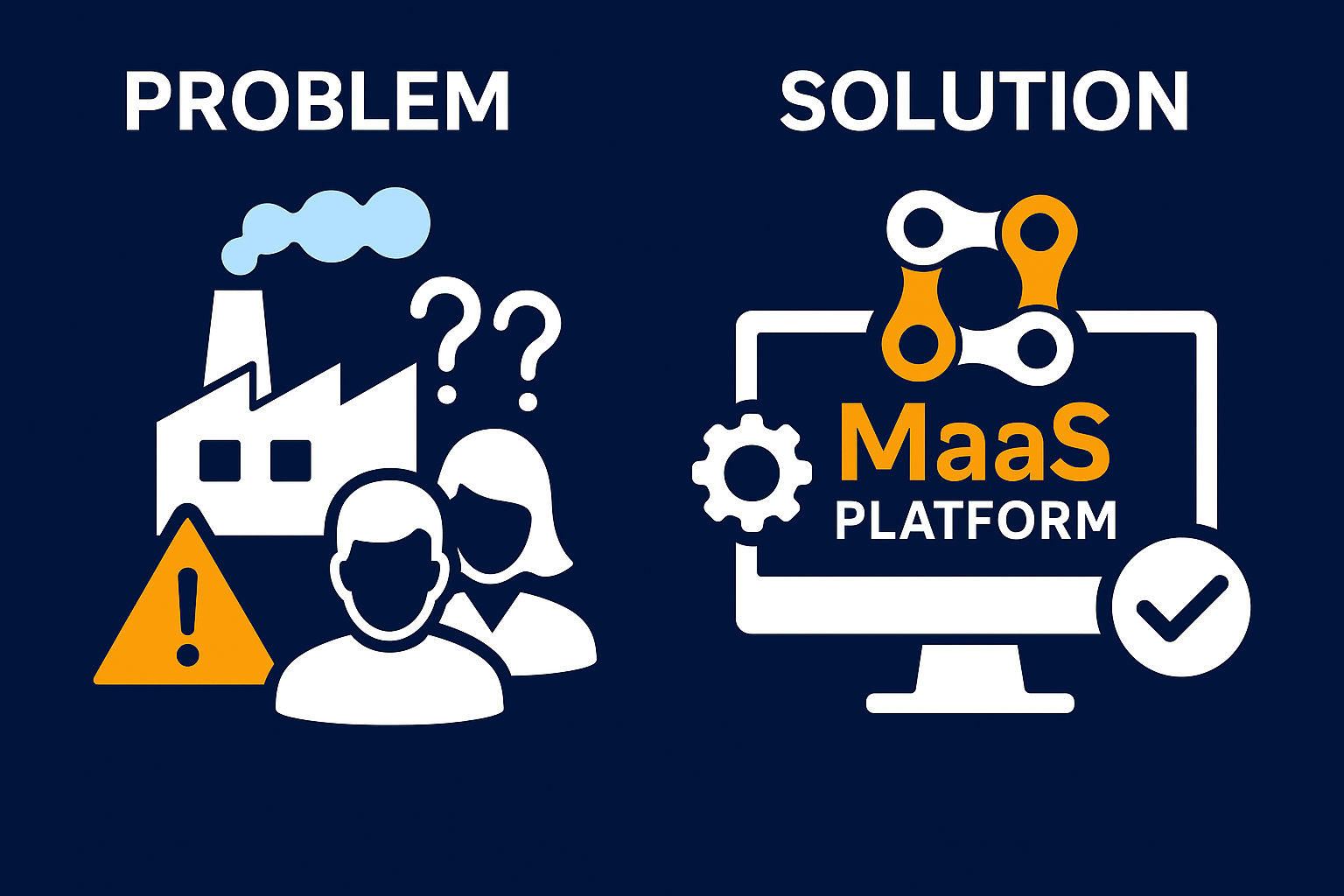

Problem

•High labor intensity for workpiece handling and setup, often leading to low precision and efficiency.

•Manual processes that increase physical burden and reduce stability.

•Shortage of companies capable of meeting strict quality standards despite having the necessary equipment.

•A rigid, trust-based supply chain that relies on word-of-mouth, limiting access to alternative partners and auxiliary equipment.

•Inefficiency and lack of flexibility in traditional supply chains, making it difficult to adapt to disruptions or rapidly changing demands.

Solution

•Enable Smart Manufacturing: Connect manufacturers with the necessary technologies, equipment, and services for bulky part production.

•Optimize Value Chains: Transform rigid supply chains into flexible, responsive networks.

•Improve Productivity and Precision: Reduce manual tasks and enhance automation, resulting in higher efficiency and accuracy.

•Ensure Sustainability: Minimize environmental impact while maintaining quality standards.

•Foster B2B Collaboration: Redefine supplier and customer relationships through a networked, digital production model, allowing easier access to resources and alternative manufacturing partners.

Business hour

Our support available to help you 24 hours a day, seven days a week.

Monday-Friday: 9am to 5pm

Saturday: 10am to 2pm

Sunday: Closed

Monday-Friday: 9am to 5pm

Saturday: 10am to 2pm

Sunday: Closed