Managing flexible value Networks: The REED Framework for operations

In today’s bulky-parts manufacturing landscape, agility and transparency are no longer optional—they are essential. Rigid workflows, data silos, and a lack of resilience to disturbances are common problems with traditional production networks. By combining several digital services into a unified architecture, the REED Operational Framework overcomes these difficulties and provides order guidance from quoting to delivery with previously unheard-of responsiveness.

The system first maps out each participant's capabilities, such as machine availability, lead times, or sustainability metrics, using decentralized scheduling and digital twin representations. These factors are then compared to order requirements by automated matchmaking algorithms, which produce value-chain configurations that are optimal in terms of cost, time, and carbon footprint. In addition to speeding up quoting times, this method incorporates environmental consciousness into the decision-making process itself.

Once a value chain is defined, orchestration shifts to live execution. Real-time process tracking feeds continuous status updates into a centralized coordination layer, while secure data-space connectors ensure that each partner’s proprietary systems remain seamlessly linked. Should a tool break down or capacity constraints emerge, AI-driven feedback loops detect deviations and initiate semi-automated reconfiguration, rerouting tasks to alternative resources without manual intervention. This dynamic adaptability minimizes downtime and preserves delivery schedules even under shifting conditions.

Holistic monitoring offers end-to-end network awareness in addition to execution. Stakeholders can quickly compare actual and predicted results thanks to the unified dashboard that aggregates key performance parameters including cycle times, throughput rates, and emission levels. By highlighting areas that need attention, threshold-based alerts enable fast remedial action or, if required, a new setup cycle. Future projections are improved by the ongoing learning that environmental impact analytics incorporates, leading to ever-increasing sustainability and efficiency.

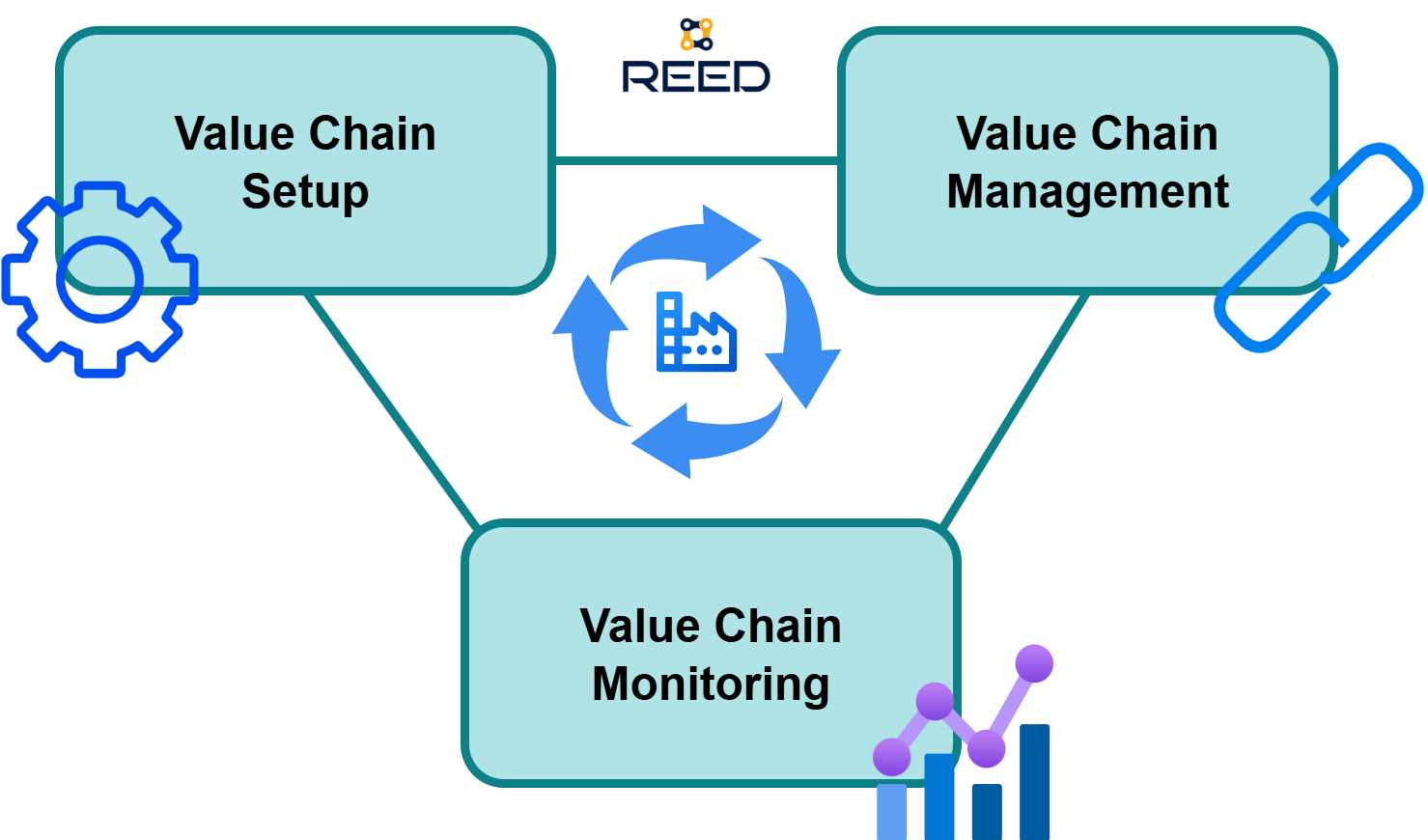

The strength of the REED Operational Framework lies in its modular sub-frameworks for setup, management, and monitoring. By clearly delineating these layers, the architecture remains both scalable and flexible, accommodating new partners, technologies, and market demands without extensive redevelopment. Manufacturers gain the ability to reconfigure their networks on the fly, respond to regulatory or customer requirements, and pursue circular-economy strategies with digital product passports—all within a single, interoperable system.

This operational structure will be crucial in transforming innovative ideas into practical production advantages as the REED consortium moves closer to industry pilot deployments. Setting a new benchmark for the bulky-parts industry in Europe, the path ahead will demonstrate how a responsive, data-driven value network can produce quicker lead times, increased resilience, and noticeable sustainability improvements.

Author: Mavrothalassitis Panagiotis (LMS)